News and Innovations

01/2024

Smart production data recording

In future, you will be able to log all process-relevant parameters precisely and easily via the data logger module. Check the logs from the comfort of your desk!

03/2023

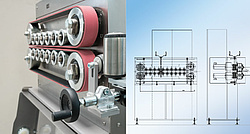

Servo cutter and take-off conveyor with intelligent control system

Bellaform supplies both individual components and complete turnkey systems with intelligent control.

02/2023

Vibrating screen for shear roller mixing systems

For the screening of your granulates Bellaform now offers a vibrating screen as an extension to your shear roller mixing system. Disturbing dust and small particles are thus reliably separated.

01/2023

Reinforcement for the servo cutter

Our servo cutter now also cuts plastic pipes with larger diameters (from 1 to 40 mm) and thicker walls(up to 2.5 mm). For this purpose, we have reinforced the machine frame, cutter bar and holder, and servo motor.

04/2022

A 1000 Takeoff – new design offers many advantages

On our newly designed A 1000 takeoff the belts of the upper and lower carriage are now controlled by two separate direct drives, so maintenance-intensive toothed belts are eliminated. In addition, both the upper and lower carriage are movable, which ensuresa stable centre and thus greater accuracy.

03/2022

Electrical monitoring of your shear roller

Increasing cost pressure leads to systems being operated with less and less staff today, which makes automated monitoring of processes ever more important. Our electrical monitoring of the pressure roll and cutting knife prevents contaminations and supports you in increasing service life while keeping costs low.

02/2022

A 1000 Takeoff – constant takeoff speed for every extrusion line!

On our newly designed A 1000 takeoff the belts of the upper and lower carriage are now controlled by two separate direct drives, so maintenance-intensive toothed belts are eliminated. In addition, both the upper and lower carriage are movable, which ensuresa stable centre and thus greater accuracy.

01/2022

Data loggers – the smart solution for recording production data

Companies must ensure the quality of their products during every stage of production. To better monitor your extrusion process – and thereby to also prevent complaints – Bellaform now offers you the option to equip your system with our new data logger. In future, you will be able to monitor logs from the comfort of your desk!

02/2021

Moveable material block for your shear roll

Our moveable material block ensures that from now on materials are no longer wasted during compound changes or when the machine is switched off. This means lower costs! Every Bellaform shear roll can be retrofitted!

01/2021

A 600 takeoff – new design offers many advantages

On our newly designed A 600 takeoff the belts of the upper and lower carriage are now controlled by two separate direct drives, so maintenance-intensive toothed belts are eliminated. In addition, both the upper and lower carriage are movable, which ensures a stable centre and thus greater accuracy.

03/2020

Corrugated Pipe Testing

As the world’s only supplier of complete systems for corrugated pipes, we are not only concerned with reliable production processes, but also with the quality of your products.

Our corrugated pipe testing measures the distance between and the diameter of the wave crests as well as the diameter of the smooth areas and the wave troughs because the intelligent camera systems of our sister Innovision GmbH are not only able to detect defects but are also suitable for the geometric measurements of products.

02/2020

Servo cutter with tool-free cutting tool changes

In addition to complete turn-key facilities, Bellaform also provides individual components, e.g. cutting equipment for continuous and discontinuous operation – to match your requirements!

Today, we present to you our new servo cutter in detail. It impresses with its tool-free quick-change system and integrated automatic cutting guide detection.

01/2020

Control system modernisation / Industry 4.0

Industry 4.0 allows for a sharp leap in productivity and profits. Those who use this development create significant competitive advantages for themselves and their customers.

Your control system has a lot of intelligence and potential, too.

In collaboration with Pütz Prozessautomatisierung GmbH we are today once more offering you the chance to adapt your control system to the technology of the future.

03/2019

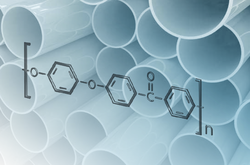

Mono-extrusion system for the

high-performance plastic PEEK

Polyether ether ketone (in short: PEEK) is a highly temperature-resilient thermoplastic high-performance plastic with many beneficial properties.

Bellaform has implemented a mono-extrusion system for testing in cooperation with our customer, granulate manufacturer Evonik Industries AG from Marl. Bellaform systems are outstanding for processing of PEEK, since they ensure a process-safe sequence even at high melting points of 330 °C.

02/2019

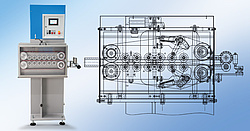

Takeoff A 275 – compact size and a convincing price

The extruder and downstream equipment such as e.g. takeoffs, are part of a complete extrusion line. Perfect coordination of all components forms the basis for first class product quality. With this in mind Bellaform is constantly working on optimising the extruder and the downstream equipment.

Our new A 275 compact take-off was specially developed for low production speeds and steady, constant pulling. It has an integrated SPS control to link it to the line control or downstream equipment. The SPS control can be customized to customer needs.

01/2019

Exclusively from the world‘s only complete system provider for corrugated pipes

As the world's only complete provider of extrusion systems for the production of corrugated pipes (mono- to five-layered pipes), we would like to inform you about one of our new developments. The Corrugator BC 58 for corrugated pipes up to Ø 58 mm offers particularly high performance (up to 47 m/min, depending on material properties and composite material). It can be integrated into existing Bellaform systems as well as into third-party systems.