Servo-Cutter

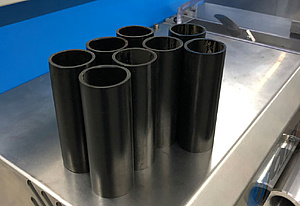

For pipes and tubes in continuous and discontinuous operation.

Freely combinable: The Servo-Cutter can be combined quickly and easily with other extrusion lines.

Flexible cutting variations: We offer you the Servo-Cutter for continuous and discontinuous operation - depending on your needs!

Manufactured entirely in Germany

Equipment features:

- Cutting guidance with quick-change system

- Scrap cutting Production rejects are ejected either via a pneumatically switchable slide or at the end of the deposing belt

- Reinforced design for cutting plastic pipes with larger diameters and and thicker walls

Outer diameter: 1 – 40 mm Wall thickness up to 2.5 mm

| Servo-Cutter | |

|---|---|

| Length x Width x Height (mm) | 600 x 800 x 2,000 |

| Max. outer diameter (mm) | 40 |

| Max. wall thickness (mm) | 2.5 mm |

| Drive servo motor (kW) | 11.9 |

| Operation | continuous and discontinuous |

| Cuts/min | 4,000 |

| Adjustable cutting length (mm) | 20 – 6,000 |

| Rotation speed (cutting speed 1/min) | 800 – max. 4,000 |

| Max. supply speed from the belt extension (m/min) | 120 |

Optional:

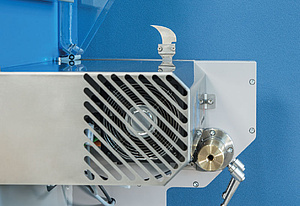

- Spraying the blade with coolant/lubricant

- Intelligently controlled take-off conveyor

- Blade heating / blade cooling

Optional extension:

Servo-Cutter and take-off conveyor are perfectly matched: The Take-off conveyor is integrated into the existing Servo-Cutter control system.

Details:

Cutting guidance with quick-change system.

Thanks to the reinforced construction of the machine frame, cutter bar, cutter holder and servo motor, larger and thicker plastic pipes can also be cut.